Acoustics Laboratory - Our Services

In order to become a complete service provider to our customers, we founded an Acoustics Laboratory and started to give service at the end of the year 2011-

Bruel & Kjaer Impedance Tube Measurements

-

Impedance tube measurements are used to compare acoustic performances of materials.Our Impedance tubes are capable of measuring sound transmission loss value

Impedance tube measurement features:

» Frequency range: 50 Hz - 6.4 kHz

» Measurement results from materials with homogenous internal structures are rather consistent

» Samples to be measured should have constant thickness and flat surface.

» During the measurements, sound pressure wave effects on the surface of the sample only with a perpendicular angle. (For more realistic measurements, alpha cabin must be used.)

» In addition to the sound absorption coefficient and sound transmission loss values, we also measure other important acoustical performance parameters such as acoustic impedance, acoustic admittance and reflection coefficient

» Mechanism used for the measurement of sound absorption coefficient

» Mechanism used for the measurement of sound transmission loss value

-

-

Vibration Tests

-

We also measure vibration loss factors of insulation materials. Thus, vibration loss features of materials in addition to their acoustic performances are determined

-

-

Alpha Cabin Tests

-

Alpha cabins are small reverberation rooms designed for the automotive sector. We designed an alpha twin cabin with two cabins in order to measure sound transmission loss value of materials. Also each cabin is capable of sound absorption coefficient tests. In these cabins, realistic environment conditions are met for the required measurements. We measure sound absorption coefficient values of car seats and car floors, and also acoustical performance of insulation materials used in bonnets.

Alpha cabins are small reverberation rooms designed for the automotive sector. We designed an alpha twin cabin with two cabins in order to measure sound transmission loss value of materials. Also each cabin is capable of sound absorption coefficient tests. In these cabins, realistic environment conditions are met for the required measurements. We measure sound absorption coefficient values of car seats and car floors, and also acoustical performance of insulation materials used in bonnets.

Alpha cabin measurement features are as follows:

» Frequency range: 400 Hz-10kHz

» Since big samples are used, consistent results are obtained for materials with both homogenous and heterogenous internal structures

» Can be used for materials with variable thickness and with flat or profiled surface.

» In comparison to the impedance tube, alpha cabin provides more realistic measurement results due to the fact that sound pressures effect on the surface of the sample in various angles.

-

-

Acoustic Performance Analyses (Comet Trim)

-

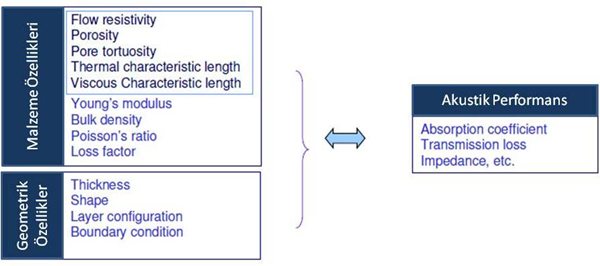

Acoustic performance analyses are conducted by using macroscopic and geometric properties of the materials. Modified Biot’s theory establishes a relationship between material, geometric properties and acoustic performance.

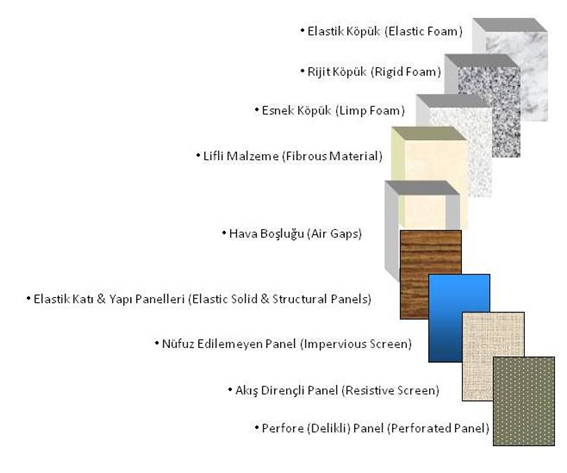

Comet Trim classifies the materials according to their macroscopic properties. This classification has been done for the materials frequently used in the industry.

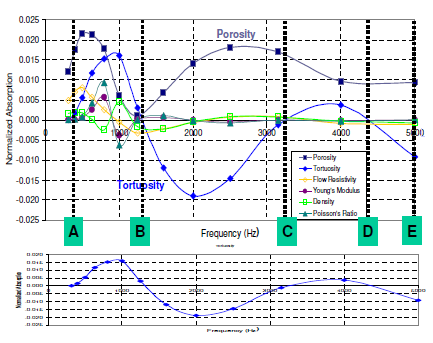

It evaluates the sensitivity of acoustical performance with respect to macroscopic properties (thickness, density, porosity etc.). Thus, it is decided what kind of materials will be used, i.e. thick or thin; more or less porous.

A-B, C-D freq. range

» Values above the axis:

» Performance will increase when the design parameter is increased

B-D D-E freq. range

Values below the axis:

Performance will decrease when the design parameter is increased

Sensitivity analyses done for a sample

-

-

Optimization Analyses

-

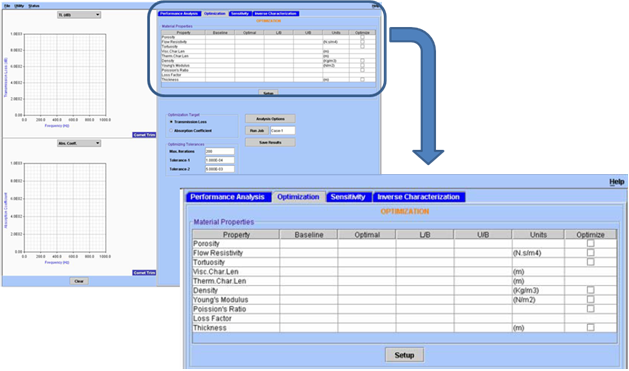

They are used to find the optimum values for macroscopic and geometric properties of materials. They differ from the sensitivity analyses such that they provide the macroscopic and geometric properties required for the optimum acoustical performance value in a definite frequency range. By using these properties, a new material can be produced.

-

-

Inverse Characterization Method

-

It is useful for inferring unkown macroscopic and geometric properties of materials from the results of measurements conducted with impedance tube before.

By using inverse characterization method, we measured most of the industrial insulation materials and found their material properties. This way we created a library of acoustical measurements.

-

CORPORATE

PRODUCTS

Formplast 2019 © All Rights Reserved.